Imprimir STL Impulsor centrifugo, estilo compressor, D280mm, para extrator de poeira Modelo 3D - 3947926

Things 3D Fila

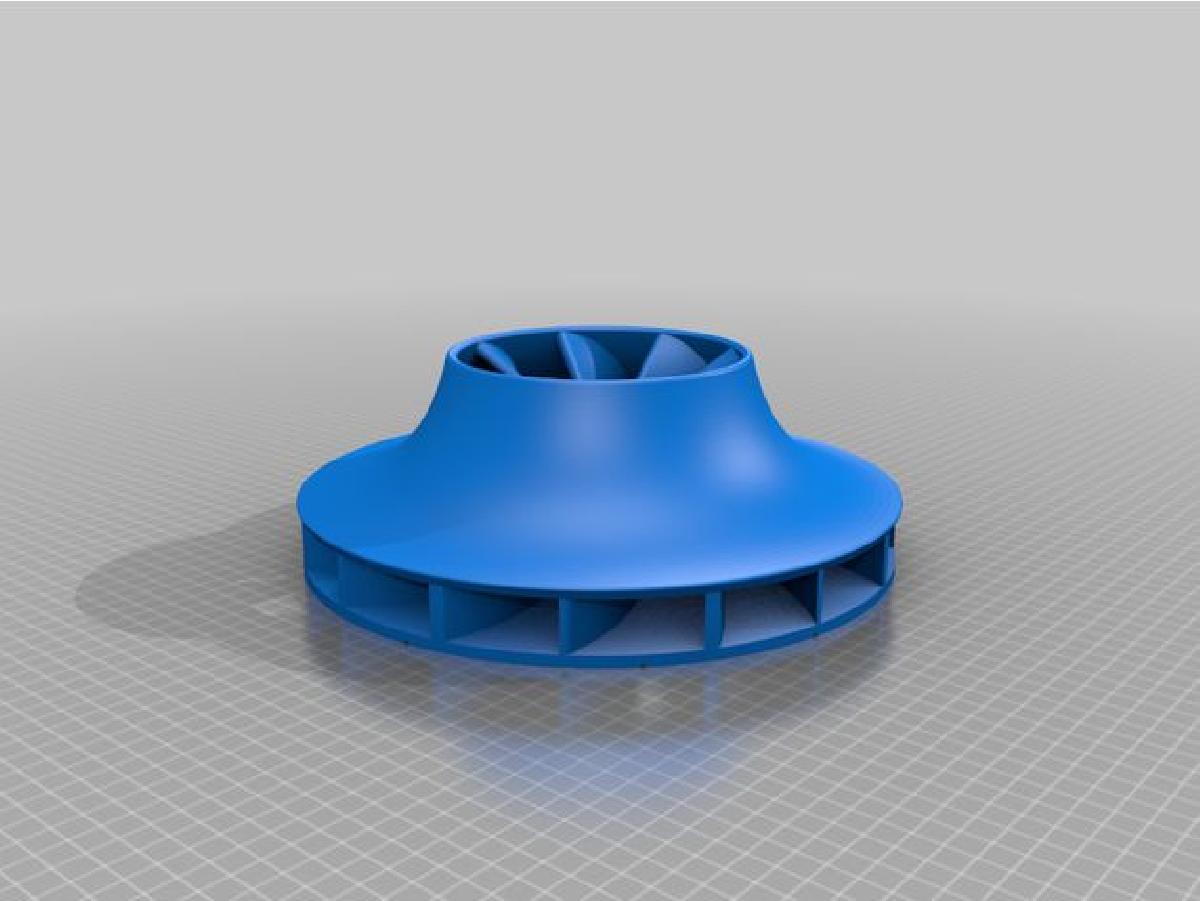

Impulsor centrifugo, estilo compressor, D280mm, para extrator de poeira

parts

Se você ainda não tem uma máquina para imprimir este arquivo pode comprar uma impressora 3d aqui!

Você pode imprimir este modelo 3d com estes filamentos ou com estas resinas 3D.

Sobre o objeto 3D Impulsor centrifugo, estilo compressor, D280mm, para extrator de poeira

Este é um arquivo desenvolvido e projetado com ferramenta CAD.

Se você ainda não sabe criar seu próprio modelo 3D eu te ensino neste artigo tutorial sobre Tinkercad.

Impulsor centrifugo, estilo compressor, D280mm, para extrator de poeira foi projetado para Impressora 3D. This design has a 10mm shaft running through it, I could probably mod this and scale the model if you like. Tips welcome of course :). The cuts etc on the base are to help it print, reduces warping. I actually printed with relatively low infill, and 1.2mm walls - pretty terrifying when spinning up for the first time, I was concerned it would explode, but it was all good.Dont ask me what the static pressure etc etc etc characteristics are - I have no idea! This was designed by looking at compressor impellers, and then just trying to figure it out. Although there is basic info online about forward/radial/reverse style blades, if there is info about the best practices on how to actually implement them, then it must be held by a bunch of ninja monks on a remote Japanese mountaintop because I sure as hell couldnt find anything online. Even regarding a simple question like whether there should be a constant cross section of flow - nothing. So I printed two smaller test impellers and, curiously, the one without a constant area had the highest flow.Picture shows the inside with the blades, without the roof or whatever it is called - second smaller blades have an aerofoil shape to them. I just suppressed later parts of the design for this pic, so it doesnt have all later features.A side note, while this is fun to print, and I have tried a few implementations including the large one uploaded here, I am not sure it will be the best option for e.g. a dust extractor. I say this because I currently have two cheap DC01 vacuum cleaner motor / impellers (in parallel) powering the extractor in my workshop - which is set up with a cyclone separator, coarse dust filter, fine filter, and then HEPA (all large, industry grade, relatively low pressure drop over). I then decided to print a 150mm version of the above impeller, designed a smooth flow inlet and nice outlet to catch and direct the circular element of the flow downwards, etc, powered by an old 350W 24v brushless motor from a broken vacuum cleaner. I then tested the air flow rate with an anemometer vs power consumption, with just the two DC01 running, with just the new setup running, or with both running, and the old DC01 motors always produced more airflow for a given total power. Not sure why, probably to do with surface roughness, tighter tolerances, etc etc. But hey, turns out well engineered vacuum motors are better!! So if you want an extractor, DC01 motors (at least here in the UK on 240V) with motor speed controllers will probably work better. I use Kemo M028N for speed control, avoid the cheap Chinese junk, they die at higher power levels. Kemo M150 can be used to allow PWM control off an arduino etc. DC01 have brushes, but replacements can be bought cheap from China when they wear out. Only question mark is pressure drop, if your have a lower pressure drop than me (my setup is pretty chunky...) then maybe this will work as well as the DC01 or better, not sure!

Não deixe de imprimir e compartilhar este modelo 3d. Não deixe sua impressora 3D parada. Mas se você não tem uma impressora 3D ainda, escolha a sua agora.